Max Feeding Size: 180mm

Adjustment Range: 15-50mm

Capacity: 2-6t/h

Motor Power: 7.5kw

Overall Dimension: 910*750*990mm

Weight: 1.3t

Power Supply: Industrial Three-phase Electricity

3-10tph jaw crusher manufacturers PE200x300 details

Sandman crusher PE200x300 jaw rock crusher feeding size is 180 mm, the output size is 15-50 mm, and capacity is 2-6 t/h. The final size can be 0-20mm(adjustable). It's mainly used at the primary stage of material reduction in several applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, metallurgy, and chemical industries. Sandman jaw rock crusher is also called coarse crusher or primary crusher. This model is usually used as primary crushing in a stone crushing line, portable type crusher, and stationary type crushing plant. This jaw rock crusher can be used for crushing all kinds of ore, waste rock, construction waste, mudstone, and other materials.

3-10tph jaw crusher manufacturers PE200x300 pictures show

3-10tph jaw crusher manufacturers PE200x300 introduction

Jaw Crusher is ideally suitable as a primary and secondary crusher for material with a compression strength of less than 320Mpa. A jaw crusher is widely used for crushing various materials like stone, granite, trap rock, coke, coal, manganese ore, iron ore, emery, fused aluminum, oxide, fused calcium carbide, lime stone, quartzite, alloys, etc, is a Single Toggle Roller Bearing machine.

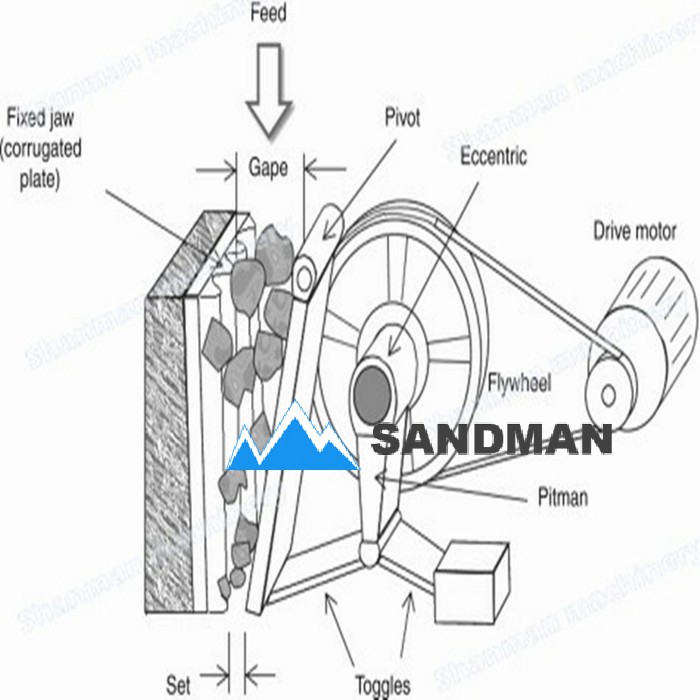

3-10tph jaw crusher manufacturers PE200x300 working principle

The electrical motor transmits power to the eccentric shaft through a v-belt and belt pulley. Then the exciting force generated by the eccentric shaft will make the movable jaw forwards and downwards. This movement would trigger the plate to push the movable jaw forwards and backward. When the movable jaw moves forth towards the fixed jaw, materials in the crushing cavity will be squashed or chopped. And then the movable jaw travels back, and the chopped or squashed materials which meted the requirement will be discharged from the outlet. Since the motor keeps working, the crusher and discharge periodically to achieve mass production.

3-10tph jaw crusher manufacturers PE200x300 features

1)Simple structure

2)Model for the latest products, a wide range of applications, with a compact structure,

3)long service life, and high work efficiency.

4)High capacity, less costly, and Easy to install.

5)The machine has a large crushing ratio, uniform product size, and simple structure,

6)convenient maintenance, which can crush the compressive strength of a variety of materials is not more than 320 MPa, is the first choice for primary crushing equipment.

7)First-class technology, and reliable pre-sale customer service quality. The products meet European CE certification standards.

8)Adjustable for easy wear parts, Easy replacement of wear and spare parts, Easy maintenance

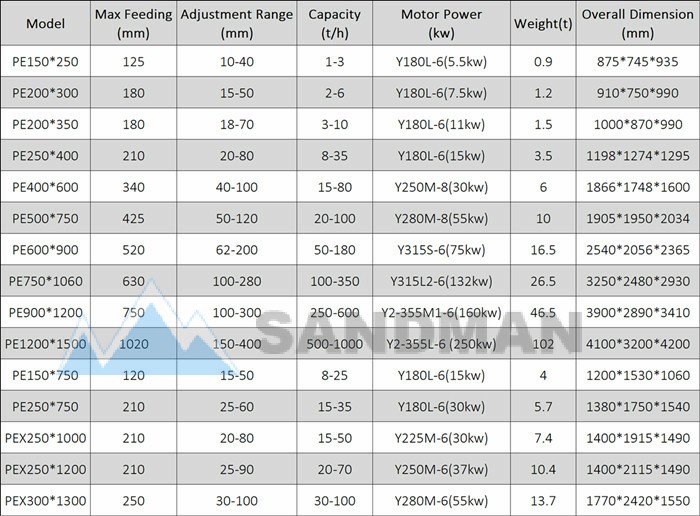

Jaw crusher specifications

3-10tph jaw crusher manufacturers PE200x300 applicable material

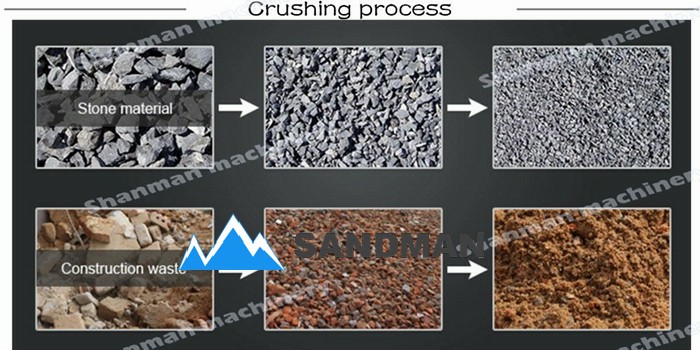

3-10tph jaw crusher manufacturers PE200x300 Crushing process

Details highly the quality

Customer visit

Packing & shipping

Questions you may have

Q: Are you a mining machinery manufacturer?

A: Yes, we are a manufacturer, and we warmly welcome clients to visit our factory at any time. We can also provide samples test, mine design, equipment manufacture, after-sale service, etc...

Q: how to choose a suitable machine?

A: To design a suitable machine, please let me know the following information:

1. what kind of stone do you want to crush? like limestone ? or granite?

2. what's the size of your stone before crushing? how many inches or mm?

3. how big capacity do you need? 2t/h?10t/h?100t/h?

4. what are your requirements for the final product size? how many inches or mm? 0-5mm? 5-20mm? Or others?

5. Do you only need one set of crushers or a whole crushing line? (Include the feeder,crusher, screen, conveyor, and so on)

6. Do you need a mobile crushing machine or a stationary one?

Q: How long is the warranty of your machine? Does your company supply the spare parts?

A: The warranty period is one year. we will supply the spare parts for you at any time.

Q: If I buy a complete mineral processing line, can you help us to build it?

A: Yes, we can help you combine a complete mineral processing line and give you related professional advice. We had already built many mining projects in China & Overseas.

Q: how about the installation?

A: Supplier provides a full set of installation drawings and instructions. If the buyer need supplier does the installation, the supplier will provide technical engineers to guide the installation, and train the buyer's workers. Buyers should take the charges for technicians and pay them a salary.

Q: What is the payment Method?

A: By T/T, L/C, Western Union, Money Gram, and so on.

Contact: Wang Hebe

Phone: +86 15092894665

Tel: +86 15092894665

Email: info@sandmancrusher.com

Add: No.23 Yihe Road,Linyi City, Shandong Province, China