【Model】M3YK1345

【Capacity】40-90 tons per hour

【Screen size】52''x160''

【Maximum input size】 <3''

【Output size】1/4'',1/2'',3/4''

【Screen decks】3

【Vibration frequency】960r/min

【Power system】Motor or Diesel engine generator

【Power】37.5kw

【Applicable material】Screening of aggregates in quarry, mining, construction industry, sand, coal,etc.

【Price】$***

Sandman Crusher features Provide you with reliable, small stone crushing and screening equipment. Vibrating screen is used to sort bulk aggregate materials by size after being crushed.

OVERVIEW

★The M3YK1345 mobile vibrating screen is in quarry operations and aggregate production to separate rocks, ores, and other materials by size, shape, or other characteristics. It includes a vibrating screen, belts,small hopper, and motors.

★This machine includes a small hopper so that you can load raw material by a small to medium-sized excavator and wheel loader.

★This machine is tire-mounted for easy use.

★vibrating screen size is 1300*4000mm,and suggested material input size is <80mm, or smaller in all directions.

★40-90 tons per hour capacity, the specific output is affected by many factors, such as the feeding smoothness, mud content of materials,the size of the feed, the smoothness of the discharge.

★Industries

→we have a wide range of customers from small to mid-sized contractors, aggregates businesses, and mining operations.

★Constractors

→reduce aggregate cost.

→create an additional revenue stream

→control your costs & production

★Producers

→improve efficiency and profitability

→cut down fuel costs and maintenance

→maximize your output while minimizing downtime.

SPECIFICATIONS

【Model】: M3YK1345

【Configuration】:hopper,vibrating screen, conveyor belts,motors.

【Power system】: motor or diesel engine generator

【Power】37.5kw

【Applicable material】Screening of aggregates in quarry, mining, construction industry, sand, coal,etc.

【Capacity】:40-90 tons per hour(average 60tph)

【Screen size】52''x160''

【Maximum input size】 <3''

【Output size】1/4'',1/2'',3/4''

【Screen decks】3

【Vibration frequency】960r/min

【conveyor belts】: 4

【Assembly time】: 5-20 days

【Warranty】: 1 year

【Lead time】: 40 days

FEATURES

√This vibrating screen drip line is long and has different screening specifications.

√The eccentric block is an exciting force, a strong exciting force.

√Sieve beams and sieve box are connected by high-strength bolts, there is no welding.

√Simple structure and convenient repair.

√The small amplitude, high frequency, and high dip structure make this machine highly efficient, has maximum life, has low power consumption, and has low noise.

√simple and intuitive button operation; low investment, low maintenance cost; reliable quality, reliable load-bearing capacity

√Quick set-up time

PARTS,SERVICE & WARRANTY

√Training: After you receive the equipment, we can send an engineer to train your engineer and workers,

Video or call training (free)

√Parts: We will provide the wearing parts service at the factory price

√Warranty:1-year warranty on all machines, excluding high-wear parts

WHY CHOOSE SANDMAN CRUSHER

√Buy direct-we are manufacturer

√Expert advice from sandman specialists

√Our sandman equipment experts help you select the right equipment.

√Reliable machine

INVESTMENT COST

→Equipment purchase cost: This simple screening equipment is very easy to install and does not require the construction of a foundation. It is recommended that you have an engineering technician who understands engineering machinery. As long as you follow our markings or instructions, it will be easy to complete the lifting within one day, so there is no need to send our engineers to the site for guidance; you can book containers for transportation, or please tell us the name of the port closest to your site, we will check the shipping cost for you.

So the cost of purchasing this equipment generally includes: equipment cost, shipping cost(depending on the shipping company's price), and some customs clearance fees are required after equipment arrives at your port.

→Operating costs: because maintenance is negligible, your primary ongoing costs will be electric fuel.

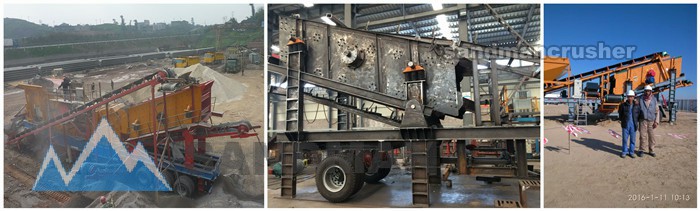

PICTURES SHOW

HOW TO CHOOSE THE SUITABLE MACHINE

To design a suitable machine, please let us know the following information:

1. what kind of stone do you want to crush? limestone? granite? Or others.

2. what's the size of your stone before crushing? how many inches or mm?

3. how big capacity do you need? 1t/h?10t/h?100t/h?

4. what are your requirements for the final product size? how many inches or mm? 0-5,5-10,10-20mm Or others?

5. Do you only need one set of crushers or a whole crushing line? (Include the feeder, crusher, screen, conveyor, and so on)

6. Do you need a mobile crushing machine or a stationary one?

Contact: Hebe Wang

Phone:

Tel: 008615092894665

Email: info@sandmancrusher.com

Add: No.23 Yihe Road,Linyi City, Shandong Province, China

We chat