Maximum feed size: 300mm

Adjustment Range: 0-60mm

Capacity: 100-260t/h

Motor power: 160kw

Dimensions: 3470*2470*2900mm

Weight: 22t

Features: impact-resistance and impact resistance of impact hammer

Large crushing area and high efficiency

Hydraulic cavity opening, convenient for maintenance

PF1315 impact concrete crusher Description

The feed size of the PF1315 impact concrete crusher is 300mm, the output is 100-260t/h, and the discharge port is adjusted to 0-60mm. And it is designed as a three-cavity crushing zone. It can crush various coarse, medium, and fine materials with compressive strength not exceeding 350Mpa. The crushing ratio is large, and the finished product is cubic, without tension and cracks. The impact concrete crusher is mainly used for the secondary crushing of the stone production line.

PF1315 impact concrete crusher Show

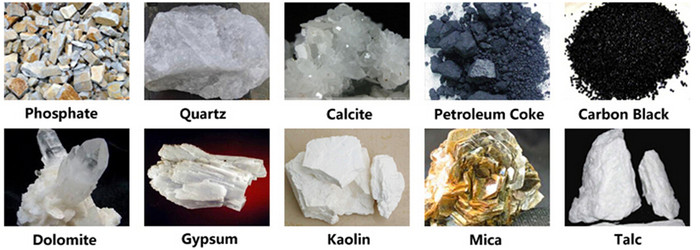

PF1315 impact concrete crusher Applicable Materials

Due to the multi-stage impact cavity of the impact crusher, there is sufficient crushing space, which is suitable for crushing large materials and has very low requirements on the properties of the materials. It can crush various soft and medium-hard ores in coarse, medium, and fine crushing. Operations, such as limestone, calcite, feldspar, talc, barite, rare earth, clay, kaolin, dolomite, gypsum, graphite, and other materials.

Choose The Right Model

To design a suitable machine, please let me know the following information:

1. what kind of stone do you want to crush? like limestone ? or granite?

2. what's the size of your stone before crushing? how many inches or mm?

3. how big capacity do you need? 1t/h?10t/h?100t/h? what are your requirements for the final product size? how many inches or mm? 0-5mm? 5-20mm? Or others?

4. Do you only need one set of crushers or a whole crushing line? (Include the feeder, crusher, screen, conveyor, and so on)

5. Do You need a mobile crushing machine or a stationary one?

Contact: Wang Hebe

Phone: +86 15092894665

Tel: +86 15092894665

Email: info@sandmancrusher.com

Add: No.23 Yihe Road,Linyi City, Shandong Province, China