Maximum feed size: 25mm

Capacity: 15-30t/h

Motor power: 380kw

Weight: 56t

Ball loading capacity: 35t

Application field: Ball mill is the key equipment for grinding after crushing in beneficiation plant

Applicable materials: copper ore, gold ore, magnetite, quartz, lead-zinc ore and other materials.

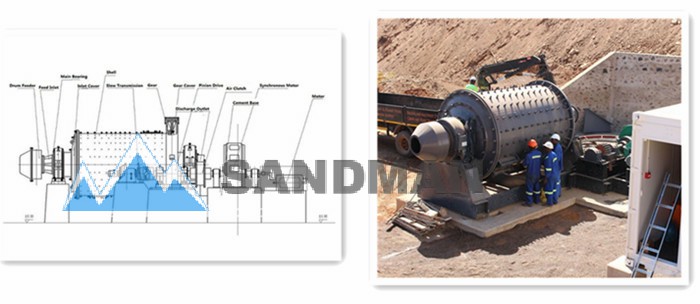

QMJ2200x7500 ball milling machine product description

The ball milling machine is the key equipment for grinding after crushing in the concentrator. It is used to grind various materials such as copper ore, gold ore, magnetite, quartz, lead-zinc ore, etc. into a fine powder of 20-75 microns. According to the discharging method, it can be divided into grate type, overflow type, etc. In addition, the ball mill can be used for dry and wet grinding of various ores and other grindable materials.

A ball milling machine is a kind of grinder, used to grind materials into a very fine powder, mainly used in the mineral processing industry. According to requirements, the ball mill can grind various ores and other materials wet or dry. The ball milling machine consists of a large cylinder that slowly rotates around a horizontal axis. The inner part of the cylinder is filled with the material to be ground and the grinding medium (metal grinding ball). In the cylinder, the medium is lifted to a certain height under the action of centrifugal force, and then falls or falls to grind the ore during the interaction between the balls. The ground feed material enters the cylinder from the hopper at one end and is discharged from the other end after being crushed by the grinding medium.

QMJ2200x7500 ball milling machine working principle and product display

The material is uniformly transported to the grinding chamber through the hollow shaft. There are step liners, corrugated liners, and steel balls of different specifications in the cavity. The centrifugal force generated by the rotation of the cylinder brings the steel ball to a certain height, and impacts and grinds the material. The ground material is discharged through the discharge plate to complete the grinding process. The ball mill is a horizontal cylindrical rotating device, driven by a wheel rim gear, with two chambers and a grid. The material enters the first cavity from the feed port. In the first cavity, there are stage lining boards, corrugated lining boards, and various steel balls. The rotation of the shell produces eccentricity. This force brings the steel ball to a certain height and then becomes a ball. The gravity drops, which affects and grinds the material. After the initial grinding in the first chamber, the materials enter the second chamber through the isolation screen. The second chamber is equipped with flat liners and steel balls. After the second chamber is crushed, the materials are discharged through the discharge screen.

Choose The Right Model

To design a suitable machine, please let me know the following information:

1. what kind of stone do you want to crush? like limestone ? or granite?

2. what's the size of your stone before crushing? how many inches or mm?

3. how big capacity do you need? 1t/h?10t/h?100t/h? what are your requirements for the final product size? how many inches or mm? 0-5mm? 5-20mm? Or others?

4. Do you only need one set of crushers or a whole crushing line? (Include the feeder, crusher, screen, conveyor, and so on)

5. Do You need a mobile crushing machine or a stationary one?

Contact: Wang Hebe

Phone: +86 15092894665

Tel: +86 15092894665

Email: info@sandmancrusher.com

Add: No.23 Yihe Road,Linyi City, Shandong Province, China