Maximum feed size: 10mm

Capacity: 40-100t/h

Motor power: 7.5kw

Power supply: industrial three-phase power

Features: Little loss of sand during washing

The structure is ingenious, and the bucket wheel transmission device is above the water surface to avoid the damage of water and sand.

Application field: Sand washing machine/sand washing machine (sand washing and screening machine) is commonly used equipment in artificial sand production line

Applicable materials: widely used in the treatment of silica sand, river sand, yellow sand, sea sand, etc., used to remove dirt and impurities in the sand, sand washing, grading, and grading to meet the standard.

XS2814 aggregate washing plant Product Introduction

Bucket wheel XS2814 aggregate washing plant is a new type of sand washing machine developed by combining the actual situation and practical experience of the sand and gravel industry. This machine is widely used in aggregate washing operations to improve the quality of sand after removing mixed stone powder and debris. The maximum feed size of XS2814 is 10mm, and the production capacity is about 40-100t/h.

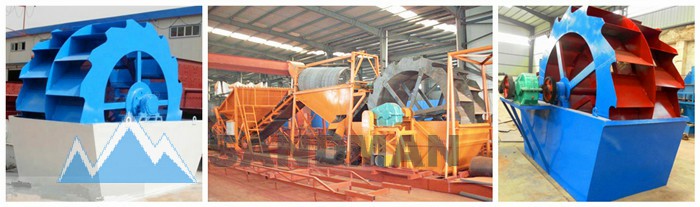

XS2814 aggregate washing plant Product Show

XS2814 aggregate washing plant applicable materials

It can be used to treat silica sand, river sand, yellow sand, sea sand, etc., to remove dirt and impurities in the sand, to wash, classify, and classify the sand to meet the standard.

Choose The Right Model

To design a suitable machine, please let me know the following information:

1. what kind of stone do you want to crush? like limestone ? or granite?

2. what's the size of your stone before crush? how many inches or mm?

3. how big capacity do you need? 1t/h?10t/h?100t/h? what are your requirements for the final product size? how many inches or mm? 0-5mm? 5-20mm? Or others?

4. Do you only need one set of crushers or a whole crushing line? (Include the feeder, crusher, screen, conveyor, and so on)

5. You need a mobile crushing machine or a stationary one?

Contact: Wang Hebe

Phone: +86 15092894665

Tel: +86 15092894665

Email: info@sandmancrusher.com

Add: No.23 Yihe Road,Linyi City, Shandong Province, China