Model NO.:PYB900

MOQ:1 Set

Power Supply:Electric

OEM:Yes

Factory Visit:Warmly Welcome

Transport Package:Plywood Box, Container

Details for cone gravel crusher PYB900

PYB900 Spring Cone Crusher has a maximum feeding particle size of 115 mm, a discharging particle size of 15-50 mm, and an output of 50-90 tons/hour. It is usually used for secondary and tertiary crushing. The standard type is suitable for medium crushing, and the medium and short head type is suitable for fine crushing. Widely used in mineral processing, building materials, water conservancy, chemical and other fields.

Pictures show for cone gravel crusher PYB900

Introduction for cone gravel crusher PYB900

PYB 600, 900, and 1200 cone crushers are widely used for medium and fine crushing in mining, chemical industry, building materials, metallurgy, and other fields. The cone crusher can crush iron ore, copper ore, limestone, quartz, granite, rock and other medium and high hardness Mohs scale materials. Standard type (PYB) is suitable for medium crushing; medium type (PYZ) and short head type (PYD) are suitable for fine crushing. The Spring cone crusher works by changing the gap in the crushing chamber.

Spring cone crusher is widely used in quarrying, metallurgy, bar, building materials, chemical industry, silicate and other industries. Ore, copper ore, limestone, quartz, granite, etc.

This spring cone crusher has a compact structure and high production efficiency. The use of bowl bearings has higher precision reserves, and the use of a concentrated thin oil lubrication system and new dry oil seal dustproof system. When it is necessary to adjust the size of the discharge opening, it can be adjusted by a hydraulic cylinder or a hand-pulled winch. A spring safety device protects the equipment from damage when non-crushing material enters the crushing chamber.

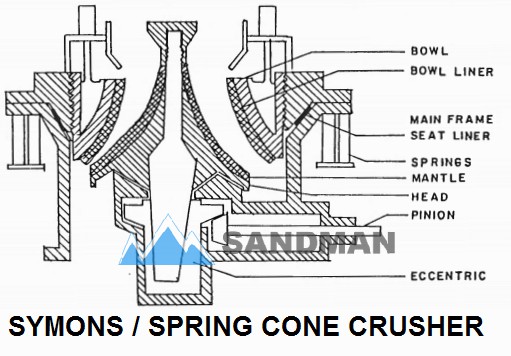

Working principle for cone gravel crusher PYB900

When the cone crusher is working, the motor drives the eccentric bearing bush through the spring coupling, transmission shaft and a pair of bevel gears. The crushing cone shaft is forced to swing under the action of the eccentric bushing, so that the casing is sometimes close to the drum lining plate, and sometimes away from the drum lining plate. The raw materials are squeezed, impacted and finally broken in the crushing chamber.

Features for cone gravel crusher PYB900

1. Good particle size

2. The adjustment of the discharge port is convenient and quick

3. Iron overload protection

4. The rolling mortar wall wears evenly and has a long service life

5. Low product maintenance cost

6. Use a dry oil seal or water seal

7. Stable operation and high reliability

8. Different types of crushing chambers to meet the needs of different customers.

9. Strong crushing force; high efficiency; high crushing capacity

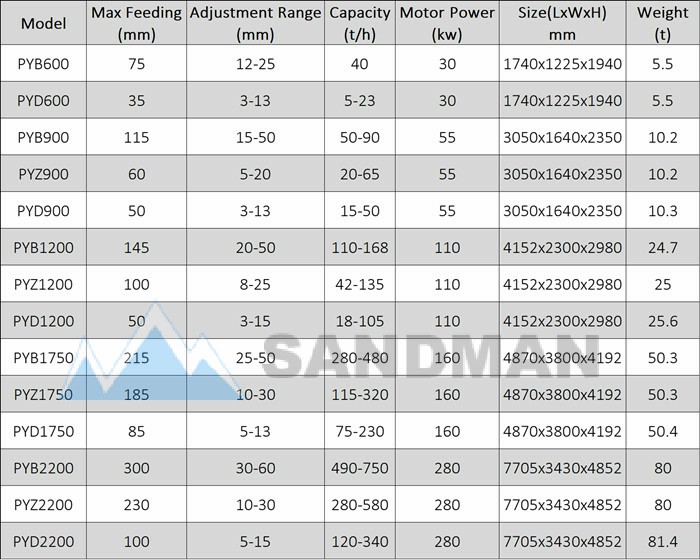

Spring cone crusher specifications

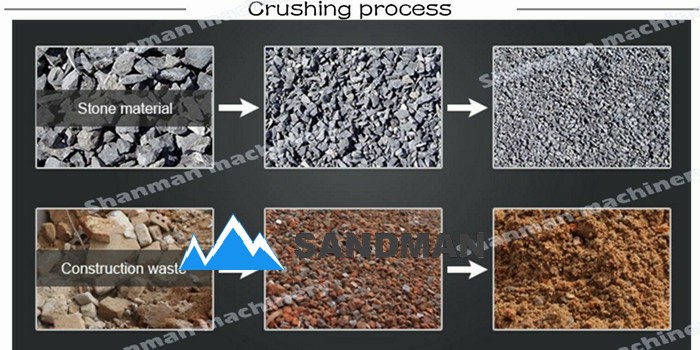

Crushing Process

Packing & shipping

Applicable Materials

Application scope of cone crusher: metallurgy, building materials, mining, chemical industry, silicate industry Applicable materials: river pebble, granite, basalt, iron ore, limestone, quartz stone, diabase, iron ore, gold ore, copper ore, Iron ore, quartz, sandstone and other medium and above medium hardness materials

Questions you may have

Q: Are you a mining machinery manufacturer?

A: Yes, we are a manufacturer, and we warmly welcome clients to visit our factory at any time. We can also provide samples test, mine design, equipment manufacture, after-sale service, etc...

Q: how to choose a suitable machine?

A: To design a suitable machine, please let me know the following information:

1. what kind of stone do you want to crush? like limestone ? or granite?

2. what's the size of your stone before crushing? how many inches or mm?

3. how big capacity do you need? 2t/h?10t/h?100t/h?

4. what are your requirements for the final product size? how many inches or mm? 0-5mm? 5-20mm? Or others?

5. Do you only need one set of crushers or a whole crushing line? (Include the feeder, crusher, screen, conveyor, and so on)

6. Do you need a mobile crushing machine or a stationary one?

Q: How long is the warranty of your machine? Does your company supply the spare parts?

A: The warranty period is one year. we will supply the spare parts for you at any time.

Q: If I buy a complete mineral processing line, can you help us to build it?

A: Yes, we can help you combine a complete mineral processing line and give you related professional advice. We had already built many mining projects in China & Overseas.

Q: how about the installation?

A: Supplier provides a full set of installation drawings and instructions. If the buyer need supplier does the installation, the supplier will provide technical engineers to guide the installation, and train the buyer's workers. Buyers should take the charges for technicians and pay them a salary.

Q: What is the payment Method?

A: By T/T, L/C, Western Union, Money Gram, and so on.

Contact: Wang Hebe

Phone: +86 15092894665

Tel: +86 15092894665

Email: info@sandmancrusher.com

Add: No.23 Yihe Road,Linyi City, Shandong Province, China