1. Advanced design technology, strong structure, and impact resistance.

2, Large feed size, high yield, good shape.

3. Super crushing, coarse, medium, and fine crushing in one step.

4. Compared with the same period last year, the output increased by 30%, and the needle flake (powder) decreased by over 20%, more energy saving

description for hammer coal crusher PC900x1200

Pc900x1000 heavy hammer crusher has a feed particle size of 400mm, a yield of 0-60mm and a production capacity of 40-80t / h. It can be used for coarse crushing and final crushing. It is a device for crushing materials in the form of impact. The heavy hammer crusher is suitable for crushing medium hard materials such as limestone, slag, coke and coal in industrial departments such as cement, chemical industry, electric power and metallurgy

display for hammer coal crusher PC900x1200

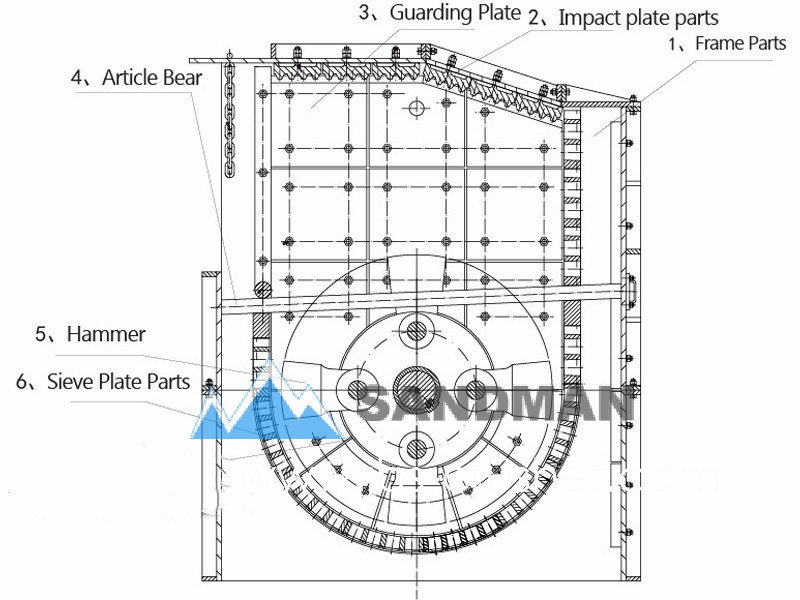

Introduction for hammer coal crusher PC900x1200

Hammer crusher is a kind of crusher that can directly crush large-size materials into very fine particles. The hammer crusher is applicable to the crushing of medium hardness materials in cement, chemical industry, electric power, metallurgy and other industrial sectors, such as the crushing and fine crushing of limestone, slag, coke, coal and other materials.

working principle for hammer coal crusher PC900x1200

The motor transmits power to the eccentric shaft through V-belt and pulley. Then, the exciting force generated by the eccentric shaft will move the movable claw forward and downward. This movement will trigger the plate to push the movable jaw forward and backward. When the movable jaw moves forward toward the fixed jaw, the material in the crushing chamber will be squeezed or chopped. The movable jaw then returns and the required shredded or crushed material will be discharged from the outlet. Due to the continuous operation of the motor, the crusher and unloading are carried out regularly to achieve mass production.

Features for hammer coal crusher PC900x1200

1. Advanced design technology, solid structure, and impact resistance.

2. The feed particle size is large, the output is high, and the molding is good.

3. Primary comminution, coarse comminution, medium comminution, and fine comminution.

4. Compared with the same period last year, the output increased by 30%, and the needle and flake (powder) decreased by more than 20%, with a better energy-saving effect.

5. The hammer head and screen plate are made of chromium manganese alloy material, with stronger impact resistance and wear resistance.

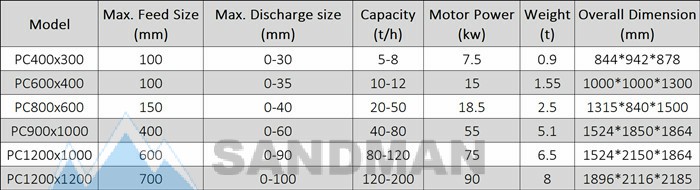

Specifications for hammer crusher

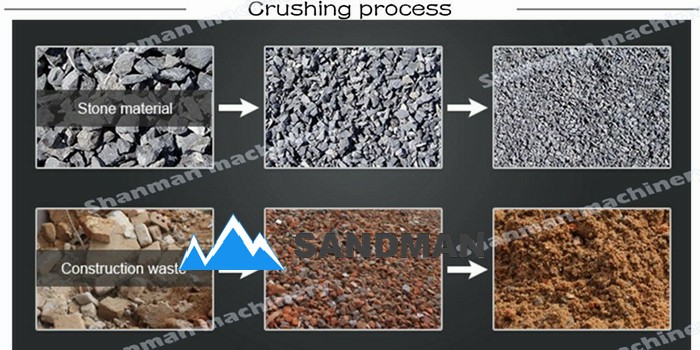

Crushing Process

Packing & shipping

Applicable materials

1. Stone field: suitable for crushing various soft and medium hard ores and rocks, such as limestone, quartzite, etc.;

2. Ore field: used in wet and dry crushing, medium and low hard material crushing, mining, cement, coal, metallurgy, building materials, road construction, petroleum and chemical industries.

Questions you may have

Q: Are you a mining machinery manufacturer?

A: Yes, we are a manufacturer, and we warmly welcome clients to visit our factory at any time. We can also provide samples test, mine design, equipment manufacture, after-sale service, etc...

Q: how to choose a suitable machine?

A: To design a suitable machine, please let me know the following information:

1. what kind of stone do you want to crush? like limestone ? or granite?

2. what's the size of your stone before crushing? how many inches or mm?

3. how big capacity do you need? 2t/h?10t/h?100t/h?

4. what are your requirements for the final product size? how many inches or mm? 0-5mm? 5-20mm? Or others?

5. Do you only need one set of crushers or a whole crushing line? (Include the feeder, crusher, screen, conveyor, and so on)

6. Do you need a mobile crushing machine or a stationary one?

Q: How long is the warranty of your machine? Does your company supply the spare parts?

A: The warranty period is one year. we will supply the spare parts for you at any time.

Q: If I buy a complete mineral processing line, can you help us to build it?

A: Yes, we can help you combine a complete mineral processing line and give you related professional advice. We had already built many mining projects in China & Overseas.

Q: how about the installation?

A: Supplier provides a full set of installation drawings and instructions. If the buyer need supplier does the installation, the supplier will provide technical engineers to guide the installation, and train the buyer's workers. Buyers should take the charges for technicians and pay them a salary.

Q: What is the payment Method?

A: By T/T, L/C, Western Union, Money Gram, and so on.

Contact: Wang Hebe

Phone: +86 15092894665

Tel: +86 15092894665

Email: info@sandmancrusher.com

Add: No.23 Yihe Road,Linyi City, Shandong Province, China