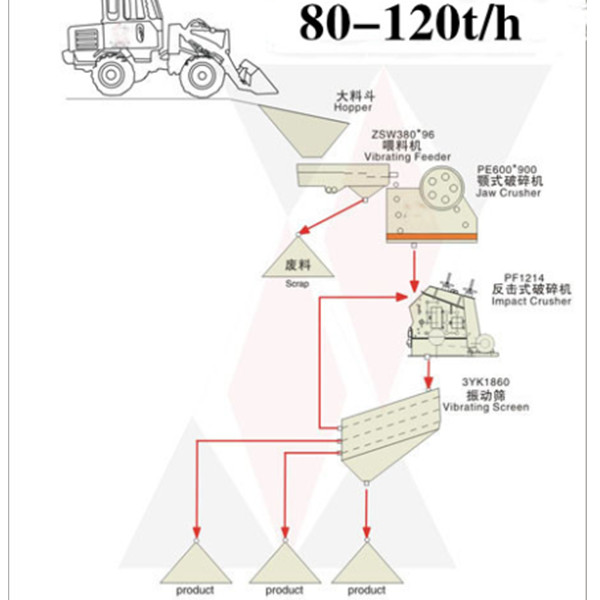

DESIGN OUTPUT

80-12t/h

MATERIAL

Limestone, granite

APPLICATION

Cement concrete, asphalt concrete, and all kinds of stable soil materials in construction projects, as well as roads, bridges, culverts, tunnels, lighting, and highway projects.

EQUIPMENT

Vibrating Federer, jaw crusher, cone crusher, round vibrating screen, belt conveyor

The stone crusher plant is used to produce aggregates of limestone, granite, basalt, river stone, marble, iron ore, dolomite, quartz, slag, etc. It is widely applied for hydraulic power, construction, highway, railway, airport runway, civil engineering projects, etc.

1. This stone crusher plant is mainly applied to medium or over-hard ores and stones, such as granite, iron ore, marble, etc. Its capacity can be 80-120 tons per hour, final aggregates size can be 0-10,10-20,20-30,30-40mm(changeable)

2. Primary jaw crusher is equipped with enhanced jaw plates and has a high reduction ratio. Mainframe and flywheels use thicker steel plates; We apply an impact crusher, cone crusher, or jaw crusher as the secondary crusher. (optional)

3. Waterpipe or other washing equipment are equipped to clean the finished products. (optional)

4. Tertiary crusher(VSI ) sand making machine or others may work as additional processing machines to diversify the final products. Tailor-made dust catcher or dust cover can also be applied to this plant. (optional)

Features

1. High degree of automatic operation; the entire production line requires almost no manual operation except for machine starting and stopping routine maintenance.

2. High productivity, low investment, and good appreciation.

3. Regular end product granularity, good grain shape, and low powder output.

4. Adopting high advanced control system to ensure security and reliable operation of the entire production line.

Configuration

Technical Description:

1. This flowchart is for reference only.

2. The actual construction should be adjusted according to the terrain.

3. The mud content of the material should not exceed 10%. The mud content will have an important impact on the output, equipment, and process.

4. Shanman can provide process plans and technical support according to the actual requirements of customers.

Contact: Hebe Wang

Phone:

Tel: 008615092894665

Email: info@sandmancrusher.com

Add: No.23 Yihe Road,Linyi City, Shandong Province, China

We chat