【Capacity】2-120 tons per hour

【Jaw opening】6''x10''--24''x36''

【Input size】 0--24''

【Output size】1/4''--4''

【Power system】Motor or Diesel engine

【Applicable materials】rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, road and railway construction, metallurgy, water conservancy, and chemical industry.

【Price】$1000--$10000USD

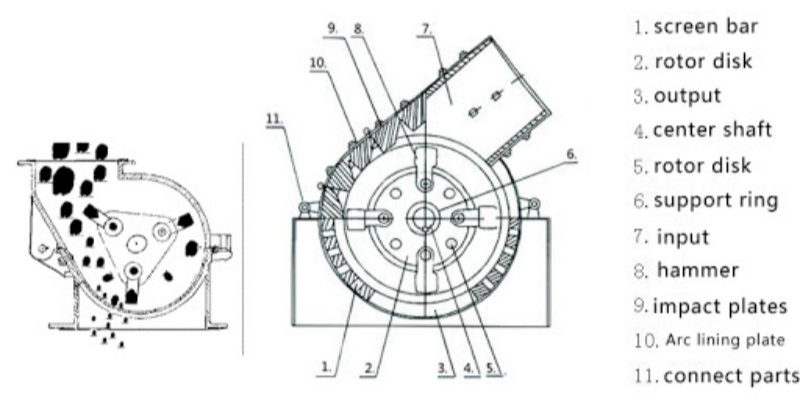

HAMMER CRUSHER INTRODUCTION

Hammer crusher is a rock crusher used in various industries to reduce the size of materials, such as limestone, coal, slag, gypsum and glass. It uses high-speed rotating hammers to impact the ore, and the finished product size can be adjusted by controlling the grate opening, rotor speed, hammer capacity, etc. Hammer crushers, such as hammer crusher or hammer crusher, can crush 100-800mm materials to 20mm or less mm. Sometimes, the application field refers to hammer crusher as crusher, such as coal crusher, coke crusher, limestone hammer crusher, brick crusher, cement hammer crusher, etc.

Hammer crushers are primarily used for breaking materials with a compression strength that is less than 200MPa, such as limestone, gypsum, coal, marlstone, and sandy shale in cement industries. The hammer crusher can crush the raw ore into small particles of 20mm in a single process, which simplifies the process when compared to traditional multi-stage crushing, thus saving customer investment costs. The hammer-crushing equipment can also be added to a complete production line.

STANDARD FEATURES

★Wear-resistant hammer head,The hammer head of the hammer crusher is the main vulnerable part. To address this shortcoming, our hammer head is made of high-quality manganese steel and has undergone strict heat treatment. It is a single austenite structure, with a service life of more than 5 times that of ordinary manganese steel and an efficiency of more than 30%.

★Large crushing ratio,The crushing ratio is large, and large pieces are crushed into uniform small pieces of products with good cubic shape. In some cases, the hammer crusher is used as a primary crusher.

★Flexibility,The hammer crusher has a compact structure, does not require a wide working space, and is easy to install and maintain. We also provide fixed, mobile and portable models (wheeled portable and crawler), which can be flexibly applied to any application.

★Triple crushing process is more energy-efficient,The crushing process of the hammer crusher is that the power drives the hammer head to crush the material, the crushed material impacts the impact plate, and the material rebounded by the impact plate hits the hammer head.

★During the entire crushing process, the material is impacted three times, but the energy is only consumed once, so the hammer crusher is more efficient and energy-saving.

★Stable operation and good crushing effect, The hammer crusher has a compact structure and all components are strictly inspected after installation, which can achieve long-term normal operation.

HOW A HAMMER CRUSHER WORKS

Material are fed into the hammer crusher, that is subject to rotation, high-speed impact and collision are broken. Qualified crushed ore is discharged through the grate, the larger size materials continue to be crushed and shattered until they reached the required size.

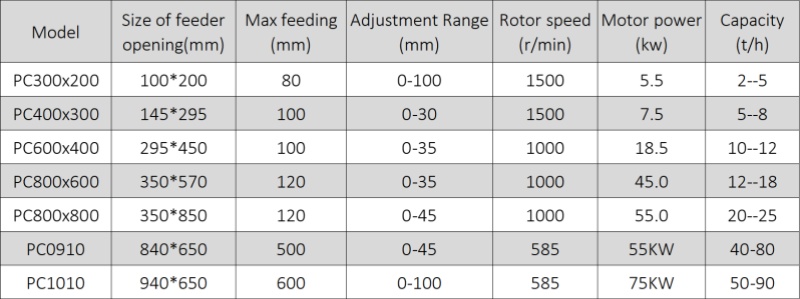

PARAMETER

PICTURES SHOW

HOW TO CHOOSE THE SUITABLE MACHINE

To design a suitable machine, please let us know the following information:

1. what kind of stone do you want to crush? limestone? granite? Or others.

2. what's the size of your stone before crushing? how many inches or mm?

3. how big capacity do you need? 1t/h?10t/h?100t/h?

4. what are your requirements for the final product size? how many inches or mm? 0-5,5-10,10-20mm Or others?

5. Do you only need one set of crushers or a whole crushing line? (Include the feeder, crusher, screen, conveyor, and so on)

6. Do you need a mobile crushing machine or a stationary one?

Contact: Hebe Wang

Phone:

Tel: 008615092894665

Email: info@sandmancrusher.com

Add: No.23 Yihe Road,Linyi City, Shandong Province, China

We chat