Model NO.:PF1315

MOQ:1 Set

Power Supply:Electric

OEM:Yes

Factory Visit:Warmly Welcome

Transport Package:Plywood Box, Container

Details for impact crusher plant PF1315

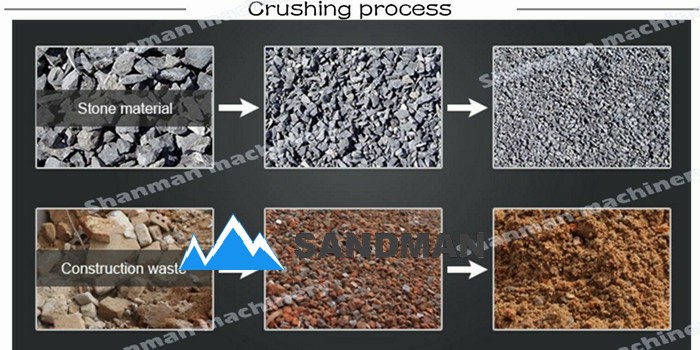

The feed size of pf1315 impact crusher is 400mm, the output size is 0-60mm, and the capacity is 160-250t / h. It is designed as a three chamber crushing area. It can crush all kinds of coarse, medium and fine materials with compressive strength not exceeding 350Mpa and side length of 100-500mm. The crushing ratio is large, and the finished product is cubic, without tension and crack. Impact crusher is mainly used for secondary crushing of stone production line.

Pictures impact crusher plant PF1315

Introduction for impact crusher plant PF1315

Impact crushers can crush stones (granite, limestone, concrete, etc.). It is widely used in ore crushing in mining, highway, railway, construction, and other industries. The practice has proved that an impact crusher is irreplaceable crushing equipment for high-grade sand and gravel

Sandman impact crusher capacity adopts a new crushing chamber design. During maintenance, the safety sensor stops the system when the door is opened. The locking system prevents the body from closing dangerously. The crusher body is made of a 10mm thick high-quality steel plate.

PF series impact crusher is widely used to produce fine materials with precise cubic shapes. Robust design increases productivity and ensures that our customers can successfully complete difficult tasks. A high reduction ratio can reduce the recycling in the crushing equipment, thus reducing the workload of vibrating screens, conveyors and other crushers

Shanman series crushers are designed to win the trust and confidence of customers. Our precision machined welded rotor has a proven structure to ensure long-term use. In addition, all parts are high-quality parts, providing customers with a trouble-free operation experience.

Our PF series grinding impact crusher has a very competitive design in the asphalt recovery process. Our experienced engineering team optimized the structure of the distributor plate to reduce the sensitivity to viscous materials and better separate these materials, which is particularly important in the asphalt recovery process. The PF series is designed with two independent crushing plates, which have also been optimized to provide better performance in the concrete recycling process.

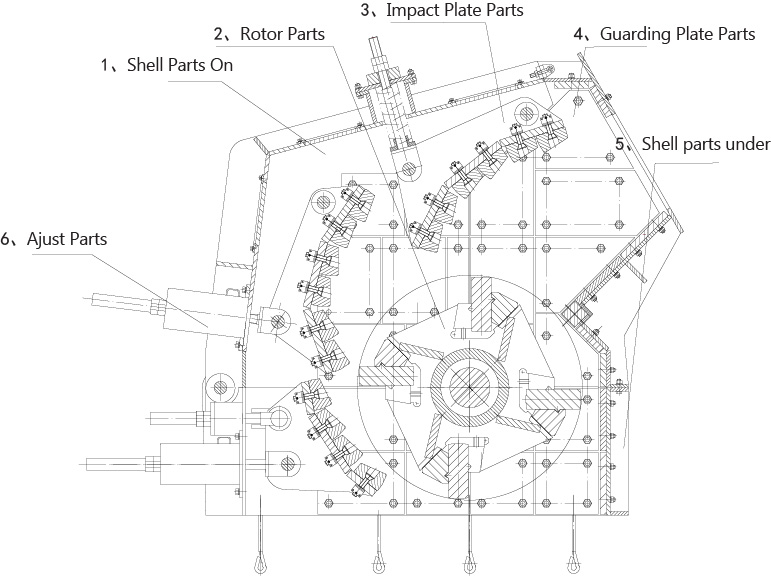

Working principle for impact crusher plant PF1315

PF series impact crusher uses impact force to break materials. When the materials enter the blow bar, they are crushed due to the high-speed impact of the blow bar, and are thrown onto the impact plate on the rotor for secondary crushing. Then, the material will bounce back to the blow rod again for a third pulverization. This process is repeated until the material is crushed to the required size and discharged from the lower part of the machine. The size and shape of the finisher powder can be changed by adjusting the gap between the impact rack and the rotor support. The machine uses a self weight safety device in its rear frame. When other objects enter the impact chamber, they will be squeezed out of the machine by the impact frames at the front and rear of the machine.

Features for impact crusher plant PF1315

1.Advanced design, High reduction ratios,high productivity

2. The blow bar with high chrome

3. Hydraulic or manual open switch

4. Special impact plate

5. Excellent,stress-free,cubical-shape products

Impact crusher specifications

Crushing Process

Packing & shipping

Applicable Materials

Questions you may have

Q: Are you a mining machinery manufacturer?

A: Yes, we are a manufacturer, and we warmly welcome clients to visit our factory at any time. We can also provide samples test, mine design, equipment manufacture, after-sale service, etc...

Q: how to choose a suitable machine?

A: To design a suitable machine, please let me know the following information:

1. what kind of stone do you want to crush? like limestone ? or granite?

2. what's the size of your stone before crushing? how many inches or mm?

3. how big capacity do you need? 2t/h?10t/h?100t/h?

4. what are your requirements for the final product size? how many inches or mm? 0-5mm? 5-20mm? Or others?

5. Do you only need one set of crushers or a whole crushing line? (Include the feeder, crusher, screen, conveyor, and so on)

6. Do you need a mobile crushing machine or a stationary one?

Q: How long is the warranty of your machine? Does your company supply the spare parts?

A: The warranty period is one year. we will supply the spare parts for you at any time.

Q: If I buy a complete mineral processing line, can you help us to build it?

A: Yes, we can help you combine a complete mineral processing line and give you related professional advice. We had already built many mining projects in China & Overseas.

Q: how about the installation?

A: Supplier provides a full set of installation drawings and instructions. If the buyer need supplier does the installation, the supplier will provide technical engineers to guide the installation, and train the buyer's workers. Buyers should take the charges for technicians and pay them a salary.

Q: What is the payment Method?

A: By T/T, L/C, Western Union, Money Gram, and so on.

Contact: Wang Hebe

Phone: +86 15092894665

Tel: +86 15092894665

Email: info@sandmancrusher.com

Add: No.23 Yihe Road,Linyi City, Shandong Province, China