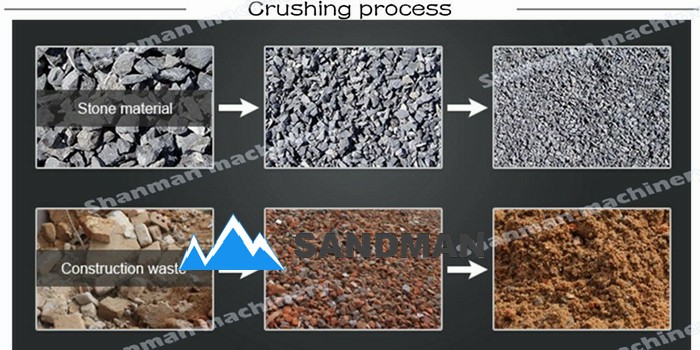

Scope of application: building aggregates, road fabrics, cushion materials, asphalt concrete, cement, etc

Applicable materials: pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone, etc.

description for rock grinder for sale QMJ2200x7500

The ball mill is the key equipment after the crushing process of the concentrator, which is used to grind various materials such as copper ore, gold ore, magnetite, quartz, lead-zinc ore into 20-75 micron fine powder. According to the discharge type, it can be grate type, overflow type, etc. In addition, the ball mill can be used for dry and wet grinding of various ores and other grindable materials.

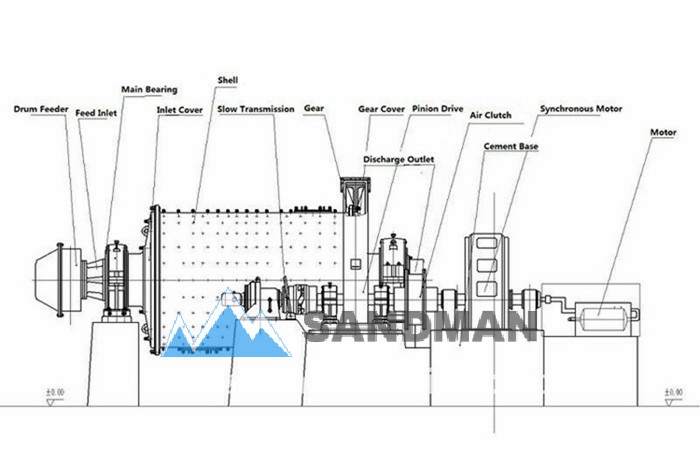

Ball mill is a kind of grinder used to grind materials into very fine powder, mainly used in mineral processing industry. The ball mill can wet mill or dry mill various ores and other materials according to requirements. The ball mill is composed of a large cylinder rotating slowly around a horizontal axis. The cylindrical part is filled with the material to be ground and the grinding medium (metal grinding ball). In the cylinder, the medium will be lifted to a certain height under the action of centrifugal force, and then fall. When they interact with each other, the ore will be ground between the balls. The feed to be ground enters the cylinder through a hopper at one end, and is discharged at the other end after being crushed by the grinding medium.

display for rock grinder for sale QMJ2200x7500

working principle for rock grinder for sale QMJ2200x7500

The ball mill is omitted from the external gear. The materials are uniformly transported to the grinding chamber through the spindle. The chamber is provided with step liner, corrugated liner and steel balls of different specifications. The centrifugal force generated by the rotation of the cylinder will bring the steel ball to a certain height, impact and grind the material. The grinding material is discharged through the discharge plate to complete the grinding process.

The ball mill is a horizontal cylindrical rotating device, driven by edge gears, and has two chambers and grids. The material enters the first chamber through the feed port. In the first chamber, there are grade liners, corrugated liners and various steel balls. The rotation of the shell generates eccentricity, which brings the ball to a certain height, and then the ball falls under the action of gravity, which will impact and grind the material. After one grinding in the first chamber, the material enters the second chamber through the isolation screen. In the second chamber, there are flat liners and steel balls. After the second grinding, the material is discharged through the discharge screen.

Features for rock grinder for sale QMJ2200x7500

1. Unique structure and stable operation.

2. Low energy consumption, large capacity and high crushing rate.

3. Perfect cubic product size and high bulk density.

4. Few spare parts, long service life and convenient replacement.

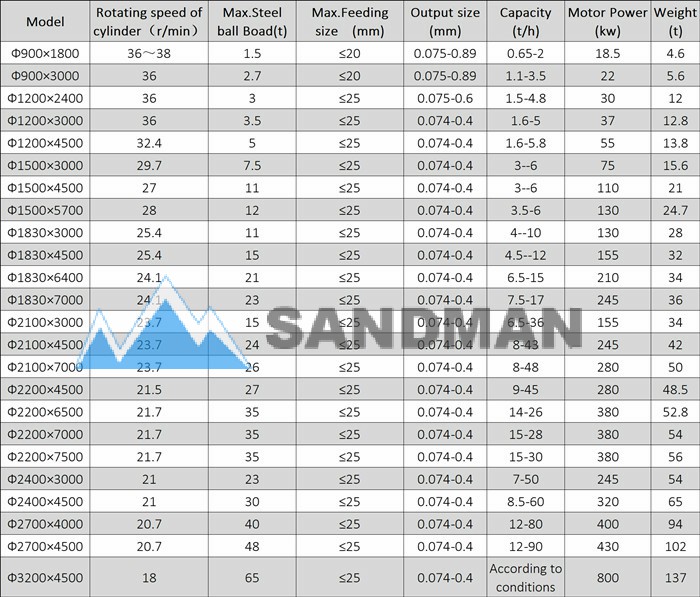

Specifications for ball mill

Crushing Process

Packing & shipping

Applicable materials

This equipment is especially suitable for high-rise buildings, highway (railway) construction, municipal engineering, large water conservancy facilities, concrete mixing plants and other fields to provide high-quality sand aggregates, which is a good choice for producing machine sand.

Questions you may have

Q: Are you a mining machinery manufacturer?

A: Yes, we are a manufacturer, and we warmly welcome clients to visit our factory at any time. We can also provide samples test, mine design, equipment manufacture, after-sale service, etc...

Q: how to choose a suitable machine?

A: To design a suitable machine, please let me know the following information:

1. what kind of stone do you want to crush? like limestone ? or granite?

2. what's the size of your stone before crushing? how many inches or mm?

3. how big capacity do you need? 2t/h?10t/h?100t/h?

4. what are your requirements for the final product size? how many inches or mm? 0-5mm? 5-20mm? Or others?

5. Do you only need one set of crushers or a whole crushing line? (Include the feeder, crusher, screen, conveyor, and so on)

6. Do you need a mobile crushing machine or a stationary one?

Q: How long is the warranty of your machine? Does your company supply the spare parts?

A: The warranty period is one year. we will supply the spare parts for you at any time.

Q: If I buy a complete mineral processing line, can you help us to build it?

A: Yes, we can help you combine a complete mineral processing line and give you related professional advice. We had already built many mining projects in China & Overseas.

Q: how about the installation?

A: Supplier provides a full set of installation drawings and instructions. If the buyer need supplier does the installation, the supplier will provide technical engineers to guide the installation, and train the buyer's workers. Buyers should take the charges for technicians and pay them a salary.

Q: What is the payment Method?

A: By T/T, L/C, Western Union, Money Gram, and so on.

Contact: Wang Hebe

Phone: +86 15092894665

Tel: +86 15092894665

Email: info@sandmancrusher.com

Add: No.23 Yihe Road,Linyi City, Shandong Province, China