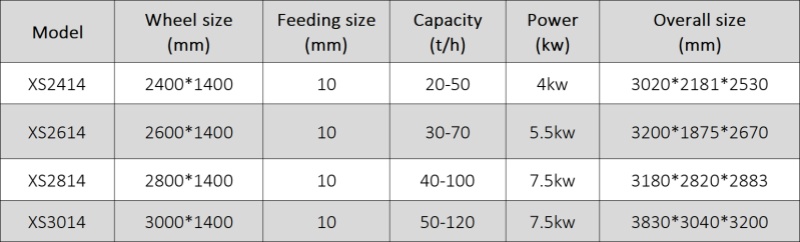

【Capacity】20-120 tons per hour

【Input size】 10mm

【Power system】Motor

【Applicable materials】 It is used to remove the dirt and impurities in sand for sand washing, classifying and grading to meet the standard.

【Price】$1000--$10000USD

BUCKET SAND WASHER INTRODUCTION

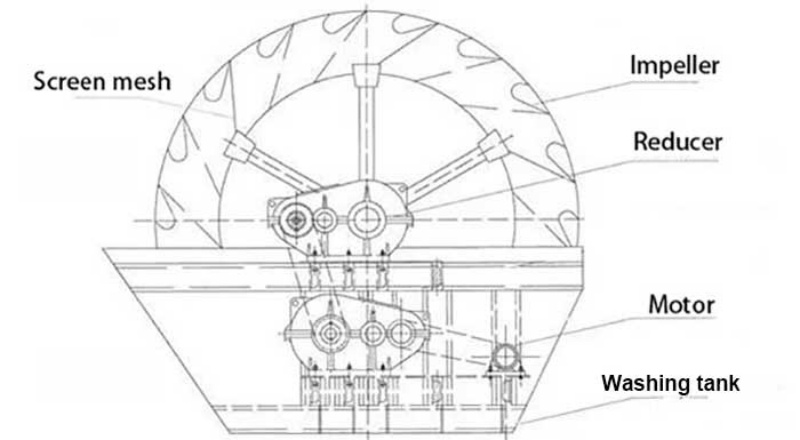

A wheel (bucket) sand washing machine is widely used to wash away dirt and impurities in the sand and improve its quality. It can also clean and separate the stone powder in the sand. Its unique sealing structure and reliable transmission device ensure the effect of cleaning and dehydration. It is widely used in sand making, mining, building materials, transportation, chemical industry, water conservancy and hydropower, concrete mixing, and other industries.

Wheel sand washing machine is used to clean and separate the dirt and other impurities in the sand to improve the quality of the sand. Due to its simple design and easy assembly process, the bucket wheel provides users with the advantages of low power consumption and water saving. It can be made into single wheel and double wheel types.

STANDARD FEATURES

★The bearing device with reasonable structure and impeller drive is isolated from water and water materials to avoid damage to the bearing due to soaking, the corrosions of sand, and pollutants;

★Little loss of medium fine sand and stone powder; lower mud content

★The machine has almost no wearing parts except the screen cloth;

★It has almost no wearing parts except the screen mesh, long service life. Long service life and convenient maintenance;

★Save water.

★Higher sand quality with a lower moisture content.

★Compact structure, multiple functions, easy installation, convenient maintenance, small occupation area.

★High capacity, after this sand washer 95% sand can be washed.

★Solve sedimentation tank cleaning problem, higher economic profit.

★The sand washing machines whose transmission gear is separated from water and sand to reduce the failure .

★The sand washing machine is indispensable equipment for sand, gravel, and aggregate washing plants and is widely used in aggregate, mines, building materials, construction, concrete, and other industries.

★Sand washers can remove the impurities covering the surface of the sand and stone to improve the sand and gravel product quality.

★Convenient maintenance, large processing capacity, low power consumption, and high cleanliness.

HOW WHEEL SAND WASHER WORKS

The sand and gravel enter the washing tank from the feed tank, tumble and grind each other under the drive of the impeller, remove the impurities covering the surface of the sand and gravel, and destroy the water layer covering the sand and gravel to facilitate dehydration. At the same time, water is added to form a strong water flow to take away the impurities and foreign objects with smaller specific gravity, and discharge them from the overflow port to complete the cleaning effect. The clean sand and gravel are taken away by the blades and finally poured into the discharge tank from the rotating impeller to complete the cleaning of the sand and gravel.

PARAMETER

PICTURES SHOW

HOW TO CHOOSE THE SUITABLE MACHINE

To design a suitable machine, please let us know the following information:

1. what kind of stone do you want to crush? limestone? granite? Or others.

2. what's the size of your stone before crushing? how many inches or mm?

3. how big capacity do you need? 1t/h?10t/h?100t/h?

4. what are your requirements for the final product size? how many inches or mm? 0-5,5-10,10-20mm Or others?

5. Do you only need one set of crushers or a whole crushing line? (Include the feeder, crusher, screen, conveyor, and so on)

6. Do you need a mobile crushing machine or a stationary one?

Contact: Hebe Wang

Phone:

Tel: 008615092894665

Email: info@sandmancrusher.com

Add: No.23 Yihe Road,Linyi City, Shandong Province, China

We chat